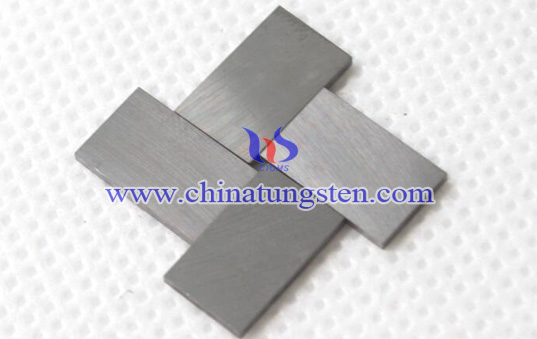

Tungsten Cemented Carbide

Tungsten cemented carbide, also called tungsten carbide, or hardmetal, is a hard material used in machining tough materials such as carbon steel or stainless steel, as well as in situations where other tools would wear away, such as high-quantity production runs. Most of the time, carbide will leave a better finish on the part, and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools.

Tungsten cemented carbide consists of tungsten carbide particles that are glued or cemented together by a relatively ductile, pure metal cobalt or nickel if corrosion is a consideration. Tungsten cemented carbide acts as "bricks" and the binder material as "mortar". Titanium carbide and tantalum carbide are added to provide heat resistance, while vanadium carbide and chromium carbide are used to control grain size and add resistance to corrosion. As the binder of tungsten carbide particles cobalt provides the best combination of hardness and strength. nickel provides corrosion resistance and freedom from magnetism. A variety of grades are available to achieve an optimum combination of properties for maximum life.

Tungsten cemented carbide is the preferred material for parts that must withstand all forms of wear (including sliding abrasion, erosion, corrosion/wear and metal-to-metal galling) and exhibit a high degree of toughness. It exhibits high compressive strength, resists deflection, and retains its hardness values at high temperatures, a physical property especially useful in metal-cutting applications. It provides long life in applications where other materials would not last or would fail prematurely.